Contact wheels

Contact wheels

Contact wheels are used as a support for the abrasive belts needed in grinding operations. The wheels are made with the best materials on the market today and are the result of years of research and experience in the sector. The processing of the metal parts is carried out with the latest generation numerical control machines while the assembly is carried out with the utmost precision. After balancing, final tests are carried out before delivery of the product to the customer.

Vulkollan® Flap Wheels with Lamellae of 5mm

Description

Vulkollan®RFlap Wheels with Lamellae of 5mm, consist of an aluminum machi- ned hub from piece full or casted and then covered with lamellae of Vulkollan®R placed horizontally on the surface with an inclination that can change depen- ding on the finishing result we want. More accentuated is the inclination, we have finest finishing and less noisy. With zero or little inclination, we have stron- ger cutting action of the belt and noisier wheel.

Sizes

The lamellae have a standard thickness of 5 mm and a height of 20/25 mm (on request available Wheels with Lamellae of 40/50/60 mm height). We produce 100 mm diameter Wheels up to 500 mm and width from 20 mm up to 150 mm (on request, even over) and with all bores.

Field of use

These wheels are generally used only for dry grinding of all metallic and non-metallic materials. Available with hardness Shore A 40/50/60. They are often used in drawing wheels of abrasive belt (engine side).

How to use

The choice of hardness is a function of grain size and flexibility of the belt. A belt with a large grained tape (from 60 to 120) shows the maximum hardness while a belt with fine grained tape (320-400-600) lists the minimum hardness.

Vulkollan® Convolute Wheels

Description

Vulkollan® Convolute wheels, consist of an aluminum machined hub from piece full or casted and then covered the whole of Vulkollan®.

Sizes

The cover has a height of 20/25 mm and, on request, we can produce Wheels with cover of 40 mm height. We produce 100 mm diameter Wheels up to 500 mm and width from 20 mm up to 150 mm (on request, even over) and with all bores.

Field of use

These wheels are generally used only for dry grinding of all metallic and non-me- tallic materials. Available with hardness Shore A from 20/25, 30/35 and 40/45.

How to use

The choice of hardness is a function of grain size and flexibility of the belt. A belt with a large grained tape (from 60 to 120) shows the maximum hardness while a belt with fine or very fine grained tape (320-400-600) lists the minimum hardness.

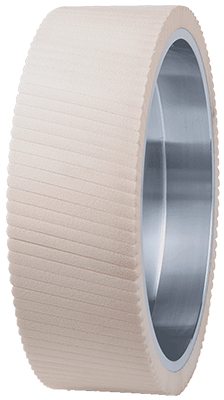

Vulkollan® Grooved Wheels

Description

Vulkollan® Grooved Wheels, consist of an aluminum machined hub from piece full or casted, covered the whole of Vulkollan® on which we made some grooves. Depending on the degree of inclination of the grooves and full/empty of them, is managed the degree of “aggression” power of the belt.

Sizes

The cover has a height of 20/25 mm and, on request, we can produce Wheels with cover of 40 mm height. We produce 100 mm diameter Wheels up to 500 mm and width from 20 mm up to 150 mm (on request, even over) and with all bores.

Field of us

These wheels are generally used only for dry grinding of all metallic and non-metallic materials. Available with hardness Shore A from 20/25, 30/35 and 40/45.

How to use

The choice of hardness is a function of grain size and flexibility of the belt. A belt with a large grai- ned tape (from 60 to 120) shows the maximum hardness while a belt with fine or very fine grained tape (320-400-600) lists the minimum hardness.

Vulkollan® and Neoprene Flat Wheels

Description

Vulkollan® and Neoprene Flap Wheels, consist of an aluminum machined hub from piece full or casted and then covered with lamellae of Vulkollan®R alterna- ted with lamellae of Neoprene. They are placed horizontally on the surface with an inclination that can change depending on the finishing result we want. More accentuated is the inclination, we have finest finishing and less noisy. With zero or little inclination, we have stronger cutting action of the belt and noisier wheel.

Sizes

Neoprene lamellae have standard thickness of 10 mm and a height of 20/25 mm, while those made of Vulkollan®, are available with a thickness of 5 mm and a height of 20/25 mm. The lamellae, normally, are assembled with a 2:1 ratio, that is, two Vulkollan® lamellae for each lamella of Neoprene. On request, we can produce wheels with lamellae of height 40/50/60 mm. We produce from 100 mm to 500 mm diameter wheels with width from 20 mm to 150 mm (on request even over) and with all bores

Field of use

These wheels are generally used for dry grinding of all metallic and non-metallic materials. Available with hardness Shore A from 10/15-20/25-30/35-40/45

How to use

The choice of hardness is a function of grain size and flexibility of the belt. A belt with a large grained tape (from 60 to 120) shows the maximum hardness while a belt with fine or very fine grained tape (320-400- 600) lists the minimum hardness.

Vulkollan® Flap Wheels with Standard Lamellae

Description

Vulkollan® Flap Wheels, consist of an aluminum machined hub from piece full or casted and then covered with lamellae of Vulkollan® placed horizontally on the surface with an inclination that can change depending on the finishing result we want. More accentuated is the inclination, we have finest finishing and less noisy. With zero or little inclination, we have stronger cutting action of the belt and noisier wheel.

Sizes

The lamellae have a standard thickness of 10 mm and a height of 20/25 mm (on request available Wheels with lamellae of 40/50/60 mm height). We produce 100 mm diameter Wheels up to 500 mm and width from 20 mm up to 150 mm (on request, even over) and with all bores.

Field of use

These wheels are generally used only for dry grinding of all metallic and non-metallic materials. Available with hardness Shore A from 10/15, 20/25, 30/35 and 40/45.

How to use

The choice of hardness is a function of grain size and flexibility of the belt. A belt with a large grained tape (from 60 to 120) shows the maximum hardness while a belt with fine grained tape (320-400-600) lists the minimum hardness.

Ruota di contatto Neoprene Liscia

Descrizione

Le Ruote in Neoprene Liscio, sono composte da un mozzo di Alluminio lavorato meccanicamente da pezzo pieno o da fusione e poi ricoperto per intero di Neoprene.

Misure

Il rivestimento ha un’altezza standard di 40/45 mm. Si possono produrre Ruote da diametro 200 mm a diametro 500 mm con larghezza da 20 mm a 150 mm (su richiesta anche oltre) e con tutti i fori.

Settore di Utilizzo

Queste Ruote sono principalmente impiegate per le operazioni di smerigliatura a secco con grane molto fini di tutti i materiali metallici e non, in special modo dove si debba seguire e rispettare dei profili.

Modalità Utilizzo

Prodotto da utilizzare a basse velocità. Ruota con elevata morbidezza. Shore A 15/18